Because of its adaptability and strength, polyvinyl chloride will lead the plastic pipe industry by 2036 with over 55% market share and 6.3% growth.[1] PVC pipes and fittings are used in corrosive situations because they withstand chemicals. Smooth interior surfaces limit friction losses, which results in high flow rates. Furthermore, PVC’s lightweight, dependable construction speeds installation and lowers project costs. It is essential for water supply, chemical processing, and waste management. Eventually, PVC piping is utilized for its durability and low maintenance.

PVC stands for polyvinyl chloride. It is a chlorinated hydrocarbon polymer. In its natural state, it is rigid and brittle. But when combined with additives such as plasticizers, it becomes more resilient and malleable. PVC pipes and fittings are utilized in fluid transport systems owing to their corrosion resistance, lightweight, and flow inside surfaces. Solvent welding joins the pipe and fittings for solid and leak-proof connections. Particularly, PVC piping is nonconductive for electrical conduits and potable water systems since it prevents electrochemical degradation. Apart from that, such pipes uphold structural integrity under thermal variations but may become brittle at low temperatures.

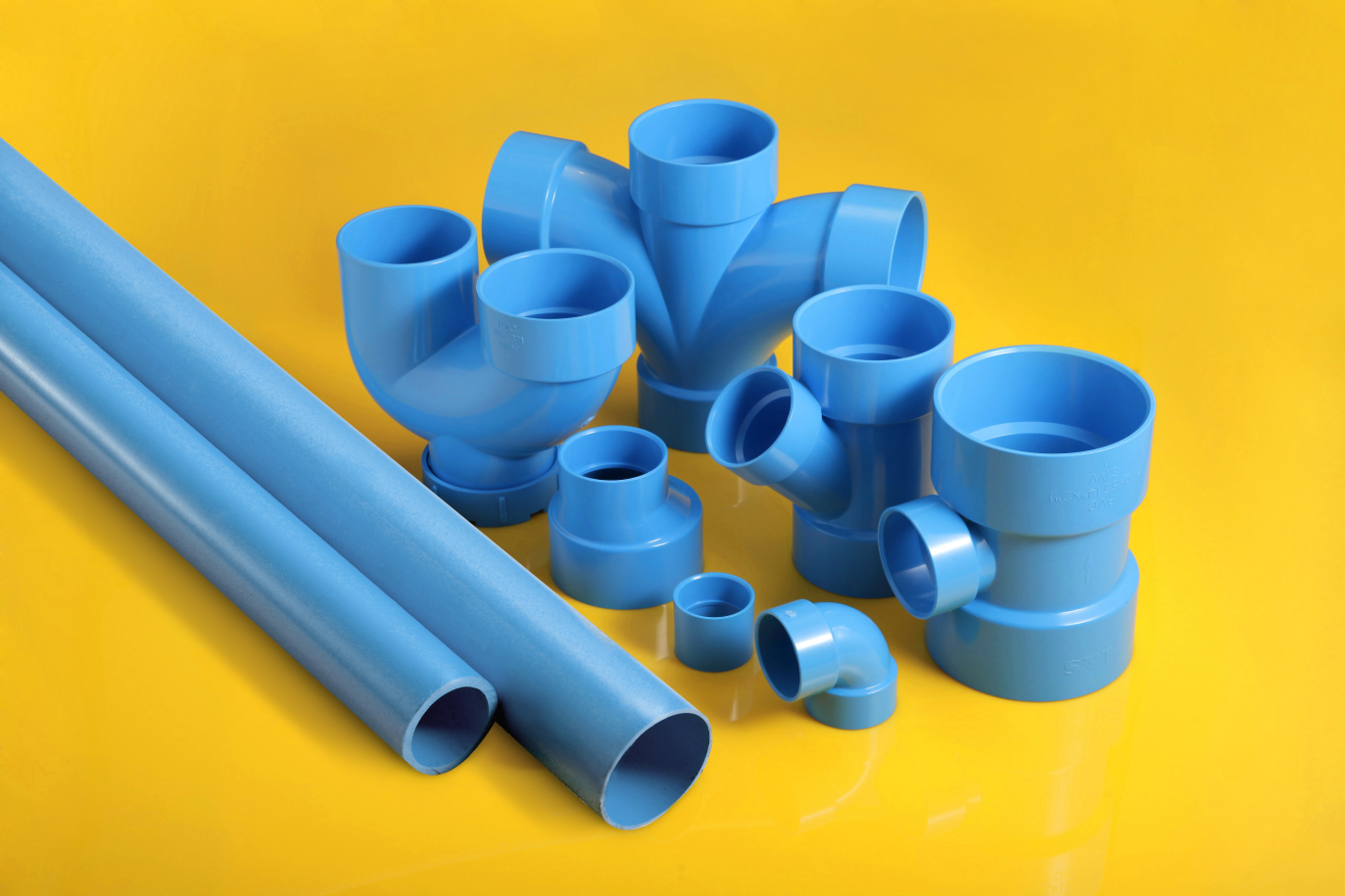

Different PVC Piping

PVC piping can be classified into types based on the application. For instance, water pipes can be scheduled 40 or 80 PVC for cold and hot water supply. They have a pressure rating and are used in residential, commercial, and irrigation systems. On the other hand, drainage pipes might be DWV (Drain-Waste-Vent) PVC. Thin walls handle low-pressure flow in sewer and wastewater systems. Wire pipes or conduits, including schedule 80 PVC, protect electrical cables for electrical applications. They resist corrosion and are fire retardant for long-term wiring systems.

Different PVC Fittings

PVC pipe fittings also vary per functionality. A coupling connects two pipes and is available in standard or reducing patterns. Elbows, 90° or 45°, change the direction of piping and are key to complex layouts. The Tee fitting splits or joins flow in a T-shaped intersection in branching systems. A cap seals a PVC pipe in temporary or permanent pipe closures. An adapter connects PVC to different materials through solvent welding or threaded ends in transitioning systems.

Size and Compatibility: Sizing is key to PVC piping systems. Pipe diameters are either nominally or by schedule. The latter indicates wall thickness. Due to its thicker walls, Schedule 80 might be needed for high-pressure applications. Always check for ASTM D1785 compliance for dimensional compatibility with valves or couplings.

Material Specifications: PVC has different grades for high-temperature applications. For instance, CPVC can handle up to 200°F, and standard PVC tops around 140°F. Resin blends with UV inhibitors or chemical resistance ensures a suitable material for corrosive settings.

Connection Method: Different fittings use solvent welding, threaded, or push-fit connections. Solvent-welded joints with primers and cements create a chemical bond. Nevertheless, threaded fittings may benefit systems requiring recurrent disassembly. The pressure rating for solvent-welded joints might be higher than for threaded connections.

Durability and Longevity: When considering the life of PVC fittings, consider temperature, pressure, and chemical exposure. PVC’s brittle nature at low temperatures should prompt rubberized or flexible fittings in such conditions. Also, thermal expansion coefficients must be considered in long piping runs to circumvent stress failure.

Manufacturer and Brand: Quality control varies between manufacturers. Look for NSF certification or ISO 9001 compliance for production standards. Brands may offer higher-strength fittings with added impact modifiers to function in punitive industrial settings.

Where PVC Pipes are Used

PVC piping is vital in plumbing for potable water lines. In irrigation systems, PVC’s low friction coefficient underrates pressure loss over long distances for water flow in agricultural fields. Its interior surface for drainage systems avoids blockages in industrial situations with debris and waste materials. Plus, PVC’s thermal insulation properties prevent condensation buildup in HVAC drainage systems for lower mold growth.

Why PVC is Ideal

PVC piping resists chemical corrosion in environments with acidic or alkaline substances, including chemical processing plants. It also bears biological growth to prevent biofilm formation in water supply systems. Besides, its lightweight nature decreases transportation and labor costs. Installers can move and cut pipes without heavy machinery. It is more apparent in large-scale projects. Hundreds of meters of piping must be laid in remote locations with logistical challenges.

We accentuate the prominence of material quality when choosing our PVC piping. Our products, made from unplasticized polyvinyl chloride (PVC-U), offer strength with pressure ratings from 0.63 MPa to 2.5 MPa. Our pipes satisfy Thailand's local standards. With sizes from 20 mm to 630 mm, we guarantee flexibility for water supply needs with a life expectancy greater than 50 years under proper utilization.

LESSO manufactures industrial PVC piping and PVC plumbing fittings. With over 50,000 m² of manufacturing area, we have an annual production capacity of 80,500 tons. We also use extrusion technology for pressure and chemical resistance. Our international-standard materials are ideal for residential and infrastructure projects because of their impact resistance and thermal stability. Our PVC-U pipes are intended for cold water delivery for reliability in various conditions. So, come to contact us for more information!

[1] Plastic Pipe Segmentation. Available at: https://www.researchnester.com/reports/plastic-pipes-market/6266 (Accessed: September 30, 2024)

TOP